New electrodes resemble tiny trees, promise big energy advantages

Using a new class of nanomaterials, a University of Wisconsin-Madison inventor is working to capture energy from the sun much as nature intended—with trees in a forest.

But these forests fit on a silicon wafer. And the trees are actually strands of titanium oxide crystals with branches 1,000 times thinner than a human hair.

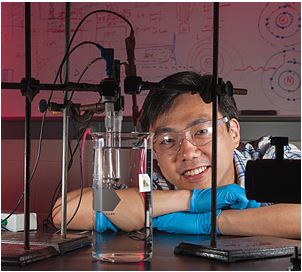

Xudong (ZHU-dong) Wang, an assistant professor in UW-Madison’s College of Engineering, has been working to create these nanowire electrode forests since he joined UW-Madison in 2008. Aided by funding from the WARF Accelerator Program, the effort now appears close to achieving key goals.

“I started working on nanowires as a graduate student in 2002 because at that time, the nanowires were a very cool, new technology and it seemed like they had the potential to solve a lot of problems,” said Wang. “We are still some months away from being able to demonstrate our findings on a commercial wafer scale, but so far we are looking at solar power energy conversion that is four times more efficient than regular nanowire-based technology. And we also see exciting applications for hydrogen fuel separation—converting water into hydrogen for use in fuel cells.”

To create the tiny trees, Wang starts with the trunks, using a patterned etching process to selectively remove excess material from the silicon wafers and sculpt tiny erect wires embedded on the silicon chip base. Growing the branches is more difficult, but necessary to achieve the density and light absorption qualities needed to capture and convert energy more efficiently.

“The branches are critical because they provide a much larger surface area than the nanowire bases alone,” Wang said. “The unique structure and chemical composition of the branches also allows for faster charge transport. It’s what makes these electrodes so much more efficient.”

While other research groups continue to struggle in this area, Wang has developed a patented process that controls the accumulation of material on the surface of the nanowires and ensures that sunlight can penetrate through the entire structure. Wang’s method involves exposing the silicon chip to alternating pulses of reactive vapor that saturates the surface growth sites upon the nanowire trunks and establishes the branches. The cycle is repeated 300 to 400 times.

“At the moment, we are on top of this technology, but this is something people have been trying to do for a long time and very competitive research groups in other countries are exploring different processes to reach the same goal,” Wang said. “There is a great deal of interest in this area because it is a clean energy technology that will improve people’s lives if we can make it commercially viable.”

Support from the Accelerator Program is now being used to scale up the technology to the point that it will be attractive for industry. Wang said he expects to be able to refine his methods, achieve greater cost savings and demonstrate technological feasibility for commercial production over the next year.

With several patents pending on the work, Wang’s three-dimensional nanowire electrode networks are part of WARF’s Clean Technology portfolio.