Clean Technology

Improved Heat Transfer Fluid Helps Sun Drive Steam Power Plants

WARF: P08455US02

Inventors: Thatcher Root

The Wisconsin Alumni Research Foundation (WARF) is seeking commercial partners interested in developing a process and system for extending the temperature range of liquid heat transfer.

Overview

Solar power is a renewable energy resource that has generated a lot of interest as an alternative to fossil fuels. Unfortunately, solar photovoltaic panels historically have been proven inefficient in converting sunlight into electrical energy. Recently, interest has grown in generating solar power for use in steam driven power plants. This process involves collecting heat from the sun using thermal panels and using the heat to warm a fluid that is used to produce high-pressure, superheated steam. The steam then can be used to power turbines in power plants. After the heat exchanging fluid has cooled, it is recirculated to the solar panels and the process begins again. To optimize the efficiency of this process, the heat absorption of the heat exchange liquid must be maximized while minimizing loss of heat throughout the system.

The key to improving the efficiency of the system is to use a heat exchanging fluid that does not evaporate or degrade at very high temperatures and also stays liquid at room temperature. Liquids used currently in solar heat collecting devices can be heated to temperatures up to 450 ºC under pressure. Higher molecular weight fluids that do not evaporate at over 500 ºC have been shown to solidify at relatively high temperatures when cooled. A process and system for liquid heat transfer at temperatures around 500 ºC are needed.

The key to improving the efficiency of the system is to use a heat exchanging fluid that does not evaporate or degrade at very high temperatures and also stays liquid at room temperature. Liquids used currently in solar heat collecting devices can be heated to temperatures up to 450 ºC under pressure. Higher molecular weight fluids that do not evaporate at over 500 ºC have been shown to solidify at relatively high temperatures when cooled. A process and system for liquid heat transfer at temperatures around 500 ºC are needed.

The Invention

UW-Madison researchers have developed a system and method for transferring heat using a variable composition heat transfer fluid that remains liquid over a wide temperature range, up to 500 ºC or above. Typically, low molecular weight fluids stay fluid at low temperatures but evaporate quickly at high temperatures, while high molecular weight fluids stay liquid at high temperatures but solidify at lower temperatures. This new system and method utilizes a heat exchanging fluid comprised of a mixture of a high boiling point, high molecular weight fluid (H), and a low freezing point, low molecular weight fluid (L).

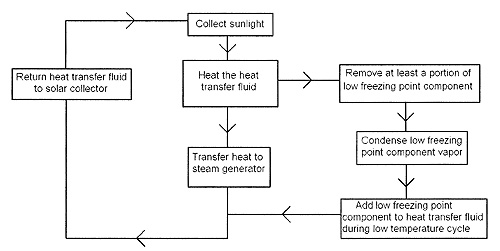

As the combined fluid mixture heats up during the heat exchange process, L evaporates and the vapor is collected in a tank and condensed back into the liquid phase, leaving the heated fluid comprised mostly of H. As the heated H is cooled after heat exchange, the liquid L is added back into the mixture to prevent H from solidifying as it cools. The high boiling point component of the mixture is useful in increasing the boiling point temperature of the heat transfer fluid and lowering the vapor pressure of the heat transfer fluid at high temperatures. The low freezing point component of the mixture is useful in lowering the freezing point temperature of the heat transfer fluid, ensuring that it does not solidify during the temperature cycle.

The system of the invention includes a vessel for containing the heat transfer fluid, a heat source, an outlet for removing some of L as temperature increases during the cycle and an inlet for re-adding L as temperature decreases during the cycle.

As the combined fluid mixture heats up during the heat exchange process, L evaporates and the vapor is collected in a tank and condensed back into the liquid phase, leaving the heated fluid comprised mostly of H. As the heated H is cooled after heat exchange, the liquid L is added back into the mixture to prevent H from solidifying as it cools. The high boiling point component of the mixture is useful in increasing the boiling point temperature of the heat transfer fluid and lowering the vapor pressure of the heat transfer fluid at high temperatures. The low freezing point component of the mixture is useful in lowering the freezing point temperature of the heat transfer fluid, ensuring that it does not solidify during the temperature cycle.

The system of the invention includes a vessel for containing the heat transfer fluid, a heat source, an outlet for removing some of L as temperature increases during the cycle and an inlet for re-adding L as temperature decreases during the cycle.

Applications

- Steam power plants using solar energy to warm heat exchange fluid

Key Benefits

- Allows raised operating temperatures, which increases the power cycle efficiency with same amount of solar energy input

- Lacks significant pressure issues because L evaporates as pressure increases when H is heated

- May be configured to utilize a nitrogen blanket to compensate for pressure issues

Additional Information

For More Information About the Inventors

Tech Fields

For current licensing status, please contact Emily Bauer at [javascript protected email address] or 608-960-9842

Figures