Clean Technology

Piezoelectrochemical Effect Uses Wasted Mechanical Energy to Split Water for Hydrogen Production

WARF: P08332US02

Inventors: Xiaochun Li, Huifang Xu, Kuang-Sheng Hong

The Wisconsin Alumni Research Foundation (WARF) is seeking commercial partners interested in developing a new technique for hydrogen production that utilizes direct water-splitting through the conversion of mechanical energy into chemical energy.

Overview

Hydrogen is one of the most promising alternative energy sources and is expected to have enormous growth potential due to recent advances in technology. Currently, hydrogen gases are produced by methane steam reforming and the electrolysis of water. But the former produces CO2 that is released into the atmosphere, and the latter uses electricity generated from fossil fuels.

The recent development of a hydrogen production technique using solar energy, called photocatalysis, has triggered large amounts of research. While progress has been made, this method has many limitations relating to efficiency, cost and device life-time. A mature hydrogen production technique that can be put to daily, commercial use is needed.

The recent development of a hydrogen production technique using solar energy, called photocatalysis, has triggered large amounts of research. While progress has been made, this method has many limitations relating to efficiency, cost and device life-time. A mature hydrogen production technique that can be put to daily, commercial use is needed.

The Invention

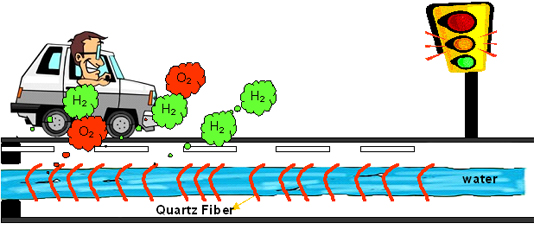

UW-Madison researchers have developed a new technique for hydrogen production that utilizes direct water-splitting through the conversion of mechanical energy into chemical energy. Certain materials, such as quartz, have intrinsic piezoelectric properties. When mechanical force is applied to these materials, they create an electric response on their surface. This electric charge then can interact with the surrounding chemical species. In the current invention, the surrounding environment is aqueous and the interaction catalyzes a water-splitting reaction that produces hydrogen and oxygen gas.

Because the process requires simple mechanical force, many potential applications exist. Some possible sources of mechanical energy include the forces exerted on roadways or walkways where cars or pedestrians pass over, or even the force of sound waves hitting a surface.

Implementing such a system is made more cost effective by the fact that quartz, a possible piezoelectric material, is one of the most abundant minerals on Earth’s surface as well as environmentally friendly. The technique also surpasses the inefficiencies of solar techniques and has shown hydrogen production rates 25 times greater than standard photocatalysis.

Because the process requires simple mechanical force, many potential applications exist. Some possible sources of mechanical energy include the forces exerted on roadways or walkways where cars or pedestrians pass over, or even the force of sound waves hitting a surface.

Implementing such a system is made more cost effective by the fact that quartz, a possible piezoelectric material, is one of the most abundant minerals on Earth’s surface as well as environmentally friendly. The technique also surpasses the inefficiencies of solar techniques and has shown hydrogen production rates 25 times greater than standard photocatalysis.

Applications

- Hydrogen gas production using wasted mechanical energy

Key Benefits

- Converts wasted mechanical energy to hydrogen production

- Quartz is one of the most abundant minerals on Earth.

- Quartz is environmentally friendly.

- Quartz has intrinsic piezoelectric properties and needs no physical/chemical doping, chemical additives or any form of implantation.

- Produces hydrogen gas at a higher rate than photocatalysis

- Only byproduct is oxygen gas.

Stage of Development

Experimental results showed hydrogen production rates on the order of 10 to 75 ppm/hr (normalized to 1.0 grams). This rate is 25 times greater than standard photocatalysis.

Additional Information

For More Information About the Inventors

Publications

For current licensing status, please contact Michael Carey at [javascript protected email address] or 608-960-9867

- Hong K.S., Xu H., Konishi H. and Li X. 2010. Direct Water Splitting Through Vibrating Piezoelectric Microfibers in Water. J. Phys. Chem. Lett. 1, 997-1002.

- Click here for a news release describing this technology.

Figures