Clean Technology

Woody Biomass Sulfite Pretreatment to Overcome Lignocellulose Recalcitrance for Biofuel Production

WARF: P08193US

Inventors: Xuejun Pan, Roland Gleisner, Gaosheng Wang, JunYong Zhu

The Wisconsin Alumni Research Foundation (WARF) is seeking commercial partners interested in developing a robust sulfite-based pretreatment for lignocellulosic biomass, a promising source of renewable energy. This pretreatment overcomes lignocelluloses recalcitrance to allow for energy efficient production of biofuels, biochemicals and other bioproducts.

Overview

Some experts in the oil industry and geological fields believe global oil reserves will reach peak production within the next twenty years. They believe that the annual supply of petroleum-based products then will begin to decline and their prices will skyrocket unless attractive substitutes or alternatives are developed. The product of greatest concern is gasoline and other fossil fuels, which comprise about 85 percent of annual crude oil production.

Investment opportunities and the desire to act in a socially responsibility manner make the development of alternative fuels attractive to both business and academia. Production technologies for liquid fuels from biomass are particularly appealing because they are readily usable in modern internal combustion engines and, if manufacture is driven by renewable sources of energy, produce no net emission of carbon dioxide. Two main approaches to convert the sugars in biomass to fuels have been developed--biological processes as in ethanol fermentation and catalytic processes as in aqueous phase reforming. The main barrier to the economic viability of these processes is the amount of energy required to breakdown lignocellulose to access usable sugars.

Lignocellulose provides the rigidity of plant cell walls and is comprised of cellulose, hemicellulose and lignin, which work together to give plant material its natural resistance to chemical or enzymatic hydrolysis, a phenomenon called lignocellulosic recalcitrance. Mechanical size reduction, harsh acid pretreatments and high pressure steam explosion currently are the most common methods for removing the recalcitrance caused by lignin and hemicellulose to access exploitable sugars in plant material. However, these conventional processes consume considerable amounts of electrical or thermal energy; for example, approximately 30 to 65 percent of the fuel energy derived in wood ethanol production.

Investment opportunities and the desire to act in a socially responsibility manner make the development of alternative fuels attractive to both business and academia. Production technologies for liquid fuels from biomass are particularly appealing because they are readily usable in modern internal combustion engines and, if manufacture is driven by renewable sources of energy, produce no net emission of carbon dioxide. Two main approaches to convert the sugars in biomass to fuels have been developed--biological processes as in ethanol fermentation and catalytic processes as in aqueous phase reforming. The main barrier to the economic viability of these processes is the amount of energy required to breakdown lignocellulose to access usable sugars.

Lignocellulose provides the rigidity of plant cell walls and is comprised of cellulose, hemicellulose and lignin, which work together to give plant material its natural resistance to chemical or enzymatic hydrolysis, a phenomenon called lignocellulosic recalcitrance. Mechanical size reduction, harsh acid pretreatments and high pressure steam explosion currently are the most common methods for removing the recalcitrance caused by lignin and hemicellulose to access exploitable sugars in plant material. However, these conventional processes consume considerable amounts of electrical or thermal energy; for example, approximately 30 to 65 percent of the fuel energy derived in wood ethanol production.

The Invention

UW-Madison researchers have developed an improved pretreatment process for robust conversion of biomass. This process, known as Sulfite Pretreatment to Overcome Recalcitrance of Lignocellulose (SPORL), reduces the energy consumption needed for size-reduction processes, required before enzymatic hydrolysis, by more than tenfold. The new method can employ a number of aqueous sulfite or bisulfite solutions over a wide range of pH values and temperatures to weaken the chemical structure of the plant material. It is particularly suitable for woody biomass, softwoods such as pines and other conifers that dominate many forests in the U.S., Canada, Europe and New Zealand, and hardwoods such as poplar, willow and eucalyptus that dominate temperate and boreal forests around the world.

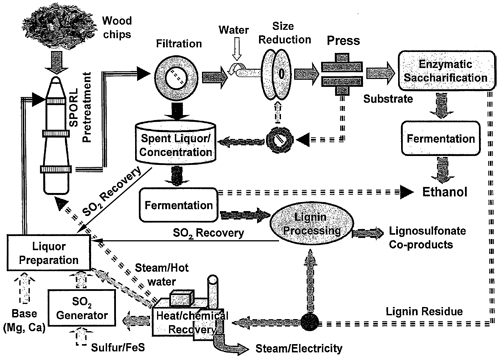

The improved SPORL approach is flexible and integrated easily into current pretreatment systems. The pH of the pretreatment liquor can be adjusted by reagent, making SPORL easily incorporated into current dilute acid approaches to improve the efficiency of the pretreatment. Mechanical size reduction steps such as disk or hammer milling can be implemented directly before or after SPORL depending on the stock material. In addition, the final enzymatic hydrolysis can be coupled directly after the pretreatment with or without washing the material or adding a surfactant to aid in the process. The pretreatment also can be employed with steam explosion, using bisulfite as a catalyst. After pretreatment, the hydrolyzed biomass can be separated and the sugars fermented or catalytically converted into fuels while sulfonated lignin byproducts can be sold to established markets and other wastes burned to produce energy for the process.

The novel SPORL approach is a superior method of biomass pretreatment because of its versatility, simplicity and efficiency. It also has excellent scalability to commercial production. The method will increase the energy efficiency of ethanol fermentation and catalytic fuel production processes through decreased size-reduction energy requirements and maximized enzymatic cellulose conversion in a short period of time. This increase in efficiency will allow biofuels and other bioproducts to become economically competitive with petroleum derived fuels and products.

The improved SPORL approach is flexible and integrated easily into current pretreatment systems. The pH of the pretreatment liquor can be adjusted by reagent, making SPORL easily incorporated into current dilute acid approaches to improve the efficiency of the pretreatment. Mechanical size reduction steps such as disk or hammer milling can be implemented directly before or after SPORL depending on the stock material. In addition, the final enzymatic hydrolysis can be coupled directly after the pretreatment with or without washing the material or adding a surfactant to aid in the process. The pretreatment also can be employed with steam explosion, using bisulfite as a catalyst. After pretreatment, the hydrolyzed biomass can be separated and the sugars fermented or catalytically converted into fuels while sulfonated lignin byproducts can be sold to established markets and other wastes burned to produce energy for the process.

The novel SPORL approach is a superior method of biomass pretreatment because of its versatility, simplicity and efficiency. It also has excellent scalability to commercial production. The method will increase the energy efficiency of ethanol fermentation and catalytic fuel production processes through decreased size-reduction energy requirements and maximized enzymatic cellulose conversion in a short period of time. This increase in efficiency will allow biofuels and other bioproducts to become economically competitive with petroleum derived fuels and products.

Applications

- Production of ethanol, biofuels, biochemicals or other bioproducts

- Pretreatment of biomaterials with strong physical integrity

- Recycling agricultural and forestry product wastes

Key Benefits

- Reduces energy consumption of size-reduction processes by more than tenfold

- Couples directly with enzymatic hydrolysis processes without further treatment

- Approximately 90 percent conversion of the cellulose fraction to glucose

- Maximizes hemicellulose and lignin removal and recovery

- Minimizes cellulose lost by degradation

- Minimizes cost of chemicals and reagents

- Able to process a variety of lignocellulosic biomaterials

- Able to retrofit existing pulping mills or equipment to produce biofuels

- Excellent scalability for building new cellulosic ethanol plants

- Sulfonated lignin byproducts can be sold as dispersants and extenders

Stage of Development

The process was tested with dried wood chips and chops of corn stalks impregnated with a bisulfite solution, ranging from a pH of 1 to 10, at a temperature of 180 degrees C for 30 minutes, immediately followed by mechanical size-reduction and enzymatic hydrolysis. It was found that nearly all hemicellulose and 20 percent of the lignin were removed at an optimal pH of 2 and temperature of 180 degrees C. About 90 percent of the recovered cellulose could be utilized in hydrolysis when feedstock was treated with a sulfite pretreatment solution at a pH of 2 for 48 hours at a normal cellulase dosage of about 5-20 FPU/g cellulose. Adding polyethylene glycol during hydrolysis gave cellulose conversions of approximately 90 percent in 12 hours and 95 percent in 48 hours.

Additional Information

For More Information About the Inventors

Publications

For current licensing status, please contact Jennifer Gottwald at [javascript protected email address] or 608-960-9854

- Zhu J.Y., Pan X.J., Wang G.S. and Gleisner R. 2009. Sulfite Pretreatment (SPORL) for Robust Enzymatic Saccharification of Spruce and Red Pine. Biores. Tech. 100, 2411-2418.

- Zhu J.Y., Wang G.S., Pan X.J. and Gleisner R. 2009. Specific Surface to Evaluate the Efficiencies of Milling and Pretreatment of Wood for Enzymatic Saccharification. Chem. Eng. Sci. 64, 474-485.

- Wang G.S., Pan X.J., Zhu J.Y., Gleisner R. and Rockwood D. 2009. Sulfite Pretreatment to Overcome Recalcitrance of Lignocellulose (SPORL) for Robust Enzymatic Saccharification of Hardwoods. Biotech Prog. 25, 1086-93.

- Zhu W., Zhu J.Y., Gleisner R. and Pan X.J. 2009. On Energy Consumption for Size-Reduction and Enzymatic Hydrolysis of Lodgepole Pine. Presented at 31st Symposium on Biotechnology for Fuels and Chemicals.

- Zhu W., Zhu J.Y., Gleisner R. and Pan X.J. 2010. On Energy Consumption for Size-Reduction and Yields from Subsequent Enzymatic Saccharification of Pretreated Lodgepole Pine. Biores. Tech. 101, 2782-2792.

Figures