Engineering

RCCI – A Clean Compression Engine Combustion Process for High Fuel Efficiency and Low Emissions

WARF: P100054US01

Inventors: Rolf Reitz, Reed Hanson, Derek Splitter, Sage Kokjohn

The Wisconsin Alumni Research Foundation (WARF) is seeking commercial partners interested in developing a compression engine combustion process to reduce diesel engine emissions.

Overview

Diesel compression ignition engines offer higher efficiency and lower CO2 emissions than their gasoline spark ignition counterparts; however, controlling NOx and soot emissions while achieving high efficiency is a challenge. Conventional diesel engines are prone to high production of nitrogen oxides (NOx), which result in adverse environmental effects such as smog and acid rain and particulates or “soot,” which is visible as the black smoke emitted by some diesel vehicles as they accelerate from a stop. As a result, the United States and many other countries have imposed stringent emission regulations on the use of diesel engines in vehicles.

Numerous technologies have been developed to address the need for diesel engines with reduced emissions. Unfortunately, measures which reduce NOx production in an engine typically increase soot production, and measures that reduce soot production commonly increase NOx production. This conundrum is often termed the “soot-NOx tradeoff.” An alternate approach is to install “after-treatment” systems that address soot and NOx after leaving the engine, but these methods tend to be expensive to install and maintain and can reduce the vehicle’s fuel efficiency. Current technologies developed to reduce both NOx and soot generation are difficult to implement and control and many still require expensive after-treatment measures. As a result, a significant need is felt for engines that provide the efficiency of a diesel engine while meeting or exceeding current emissions standards.

Numerous technologies have been developed to address the need for diesel engines with reduced emissions. Unfortunately, measures which reduce NOx production in an engine typically increase soot production, and measures that reduce soot production commonly increase NOx production. This conundrum is often termed the “soot-NOx tradeoff.” An alternate approach is to install “after-treatment” systems that address soot and NOx after leaving the engine, but these methods tend to be expensive to install and maintain and can reduce the vehicle’s fuel efficiency. Current technologies developed to reduce both NOx and soot generation are difficult to implement and control and many still require expensive after-treatment measures. As a result, a significant need is felt for engines that provide the efficiency of a diesel engine while meeting or exceeding current emissions standards.

The Invention

UW–Madison researchers have developed a compression engine combustion process using in-cylinder fuel blending. The system utilizes at least two fuels of different reactivity and multiple injections to control in-cylinder fuel reactivity to optimize combustion phasing, duration and magnitude. The process involves introduction of a low reactivity fuel into the cylinder to create a well-mixed charge of low reactivity fuel, air and recirculated exhaust gases. The high reactivity fuel is injected using single or multiple injections directly into the combustion chamber.

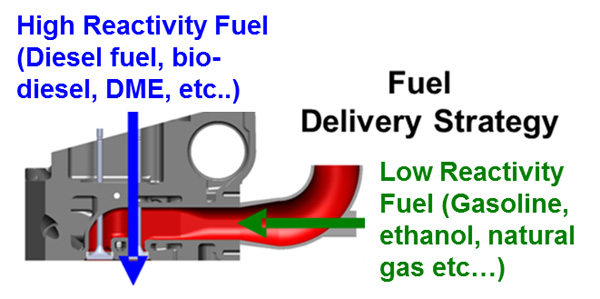

In this combustion process, the combusting phasing and duration are controlled by the auto-ignition characteristics, or reactivity of the charge; thus, the combustion mode was named Reactivity Controlled Compression Ignition (RCCI) combustion. Figure 1 shows a typical setup for RCCI combustion using port-fuel-injection of a low reactivity fuel (e.g., gasoline) and direct-injection of a high reactivity fuel (e.g., diesel fuel).

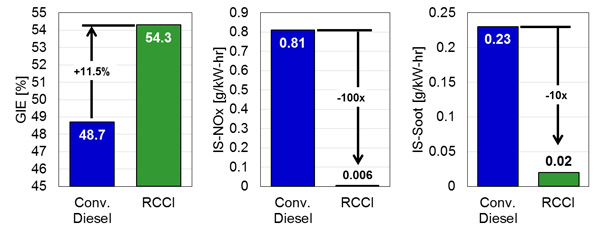

By appropriately choosing the reactivities of the fuel charges, their relative amounts, timing and combustion can be tailored to achieve maximum fuel efficiency. This methodology has resulted in what is believed to be the most fuel-efficient internal combustion engine currently known that is also capable of meeting government soot and NOx emissions limits (see related publication below). Figure 2 shows a summary of results at identical operating conditions for an engine operating in the RCCI combustion mode and state-of-the-art conventional diesel combustion mode. In addition to the improved efficiency, (i.e., reduced greenhouse gas emissions) due to reduced heat transfer losses and improved control over the combustion event, RCCI combustion has demonstrated a factor of 100 reduction in NOx emissions and a factor of 10 reduction in soot emissions.

In this combustion process, the combusting phasing and duration are controlled by the auto-ignition characteristics, or reactivity of the charge; thus, the combustion mode was named Reactivity Controlled Compression Ignition (RCCI) combustion. Figure 1 shows a typical setup for RCCI combustion using port-fuel-injection of a low reactivity fuel (e.g., gasoline) and direct-injection of a high reactivity fuel (e.g., diesel fuel).

By appropriately choosing the reactivities of the fuel charges, their relative amounts, timing and combustion can be tailored to achieve maximum fuel efficiency. This methodology has resulted in what is believed to be the most fuel-efficient internal combustion engine currently known that is also capable of meeting government soot and NOx emissions limits (see related publication below). Figure 2 shows a summary of results at identical operating conditions for an engine operating in the RCCI combustion mode and state-of-the-art conventional diesel combustion mode. In addition to the improved efficiency, (i.e., reduced greenhouse gas emissions) due to reduced heat transfer losses and improved control over the combustion event, RCCI combustion has demonstrated a factor of 100 reduction in NOx emissions and a factor of 10 reduction in soot emissions.

Applications

- Reduction of emissions of diesel engines to meet mandated EPA emissions regulations

- Improved fuel efficiency for low emission semi-trucks and off-highway vehicles

- Compatible with Exhaust Gas Recirculation and exhaust after-treatment methods to further reduce emissions

Key Benefits

- Lowers NOx and soot emissions

- Reduces heat transfer losses

- Increases fuel efficiency

- Eliminates need for costly after-treatment systems

- Reduces fuel system cost

- Complies with EPA 2010 emissions guidelines without exhaust after treatment

Stage of Development

The researchers have demonstrated results using both simulation software and actual laboratory engine tests.

Additional Information

For More Information About the Inventors

Related Technologies

- WARF reference number P110092US01 features methods to optimize the dual-fuel RCCI technology using throttling and sensor feedback.

- See WARF reference number P110320US01 for the RCCI method adapted for rotary engines.

- WARF reference number P01320US describes a method to effectively control combustion phasing in direct-injection, compression-ignition engines by using suitably timed multiple fuel injections.

- For more information about the use of multiple injections to reduce diesel engine emissions, see WARF reference number P01108US.

Publications

- Splitter D., Wissink M., DelVescovo D. and Reitz R. 2013. RCCI Engine Operation Towards 60% Thermal Efficiency. SAE Technical Paper 2013-01-0279. doi:10.4271/2013-01-0279.

- Read a news story about this technology.

Tech Fields

For current licensing status, please contact Michael Carey at [javascript protected email address] or 608-960-9867

Figures